Government Projects

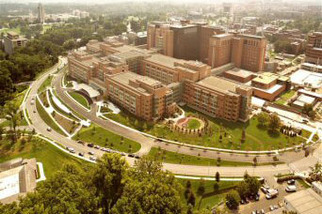

National Institutes of Health, Bethesda MarylandLDB prepared technical and economic analyses as well as specifications for a new combustion turbine generator (CTG), heat recovery steam generator (HRSG), and balance-of-plant equipment including water treatment, piping, wiring, controls and other auxiliary equipment. This cogeneration plant is capable of producing approximately 23,000 kW of electrical capacity as well as 180,000 pph of steam. This CT/HRSG addition is located in an existing building which adjoins the Central Boiler Plant. LDB has conducted energy savings analysis for the central boiler plant and related systems at the NIH Bethesda Maryland Campus.

State of KansasLDB prepared a feasibility study for the Department of Corrections, Lansing, KS to evaluate various alternatives for expanding their central heating plant and distribution system. The design and inspection of construction for the installation of two new steam boilers, the relocation and upgrading of an existing steam boiler and the installation of new hot water generators was provided. Steam and hot water services to the facility were not interrupted during construction and new plant tie-in.

U.S. Department of Energy, Pantex Plant, TexasLDB provided field investigation, design and construction inspection services for a new steam generating plant and steam distribution system (SDS) at the Pantex Plant. The comprehensive design package was developed to serve the heating and process needs of 123 existing buildings and approximately 30 future buildings. The project included over 90,000 linear feet of steam and condensate piping. A portion of the SDS included approximately 4,000 linear feet of shallow concrete trenches. LDB evaluated the use of utility tunnel, shallow concrete trenches and direct buried piping systems. The contract drawings were separated into five different construction phases. Each phase was developed into clusters of buildings in order to enable the contractor to work in a specific cluster of buildings, thus allowing production activities to continue in other clusters.

|

Offutt Air Force Base, NebraskaLDB designed the installation of a 3,000 kW diesel engine generator addition and two miles of underground circuits to furnish emergency power to critical services at the Base. A comprehensive testing program, study and report on the chilled water system for a one million square foot headquarters building was conducted. The system was modeled and evaluated for capacity and efficiency. Plans and schematics of the system were developed. An analysis was made of energy conservation opportunities (ECO).

U.S. Army Corps of EngineersLDB prepared a comprehensive technical manual for the Huntsville Division of the Corps entitled Design of Coal-Fired Boiler Plants. The purpose of the manual is to present a general guide for the design of coal-fired steam plants where the size and characteristics of the facilities processes and the economics of the particular facility justify on-site steam generation for Department of the Army installation. LDB also designed the replacement of the heating and central air conditioning for 350 family housing units at Fort Leavenworth, KS.

Veterans Administration, Kansas City, MissouriLDB has performed studies and design for the Eisenhower Medical Center in Kansas and the VA Medical Center in Missouri. Projects have involved heating, ventilation and air conditioning (HVAC) improvements for hospital wings, libraries, theaters and laboratories.

|

Robins Air Force Base, GeorgiaLDB completed a comprehensive design package for the replacement of the existing east steam and condensate piping system. The existing east steam line is a direct buried piping system. Site investigation activities included field survey of steam and condensate pipe routing, steam loads, operating pressures and temperatures, and future building plans. Several pipe routes were evaluated to minimize the amount of “downtime” to the facility. A major portion of the existing buried system was abandoned in place and new steam and condensate piping was designed for installation paralleling the existing steam route.

U.S. Department of Energy, Kansas City, MissouriLDB provided several comprehensive design packages for heating, ventilation and air conditioning (HVAC) in the Kansas City Plant. Projects involved the relocation of the manufacturing support and personnel facilities. The work involved fire protection, dehumidification, ductwork, lighting, compressed air, gaseous nitrogen, vacuum, hot and cold water, drain and liquid nitrogen systems.

Whiteman Air Force Base, MissouriLDB performed a steam distribution system study and a boiler feasibility study for the base. A significant increase in the amount of building space at the base was required to accommodate the new B-2 program creating the need to expand the capacity of the steam distribution system. Computer models of all four loops were created and analyzed to determine where existing piping would need to be replaced with larger piping to increase the capacity of the system. LDB designed a 65,000 pounds per hour boiler plant addition to the steam plant and steam distribution system based on the results of the life cycle cost and feasibility studies.

|